PE100/80 Material Sn16 Buried HDPE Double Wall Corrugated Pipes for Sewage Drainage

Basic Info

| Model NO. | Thermoplastic Pipe |

| After-sales Service | Professional After-Sales Team |

| Warranty | 50 Years |

| Material | HDPE |

| Kind | Thermosetting Plastics Pipe |

| Water Absorption | 0.1%~0.3% |

| Contraction Percentage | <0.4% |

| Tensile Strength | 81~130MPa |

| Usage | Drainpipe, Agricultural Irrigation Pipe, Corrugate |

| Length | 5.8m, 12m or as Required |

| Life Time | More Than 50 Years |

| Diameter | DN200-DN800 |

| Strength | High Strength |

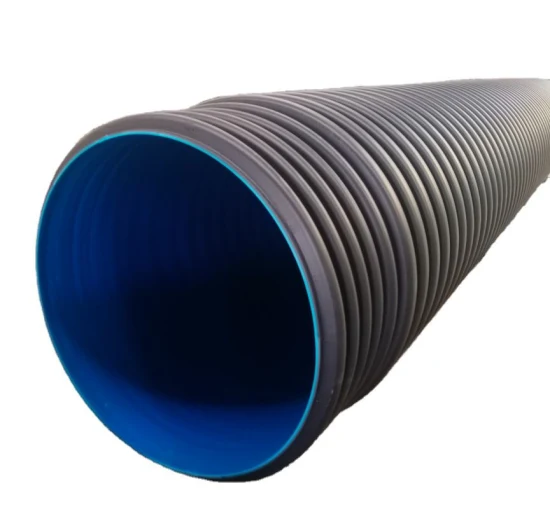

| Color | Blue |

| After-Sale Service | Online Technical Support |

| Installation | Pipe Connected |

| Standard | ISO14001, ISO9001, OHSAS/ Ohsms 18001 |

| Advantages | High Stiffness, Light Weight, Stable, Long Service |

| Fearture | Corrosion Resistant, etc |

| Certificate | ISO ,CE |

| Transport Package | Standard, Container |

| Specification | DN200-DN800 |

| Trademark | LUAO |

| Origin | China |

| HS Code | 39172100 |

| Production Capacity | 100000t/Year |

Product Description

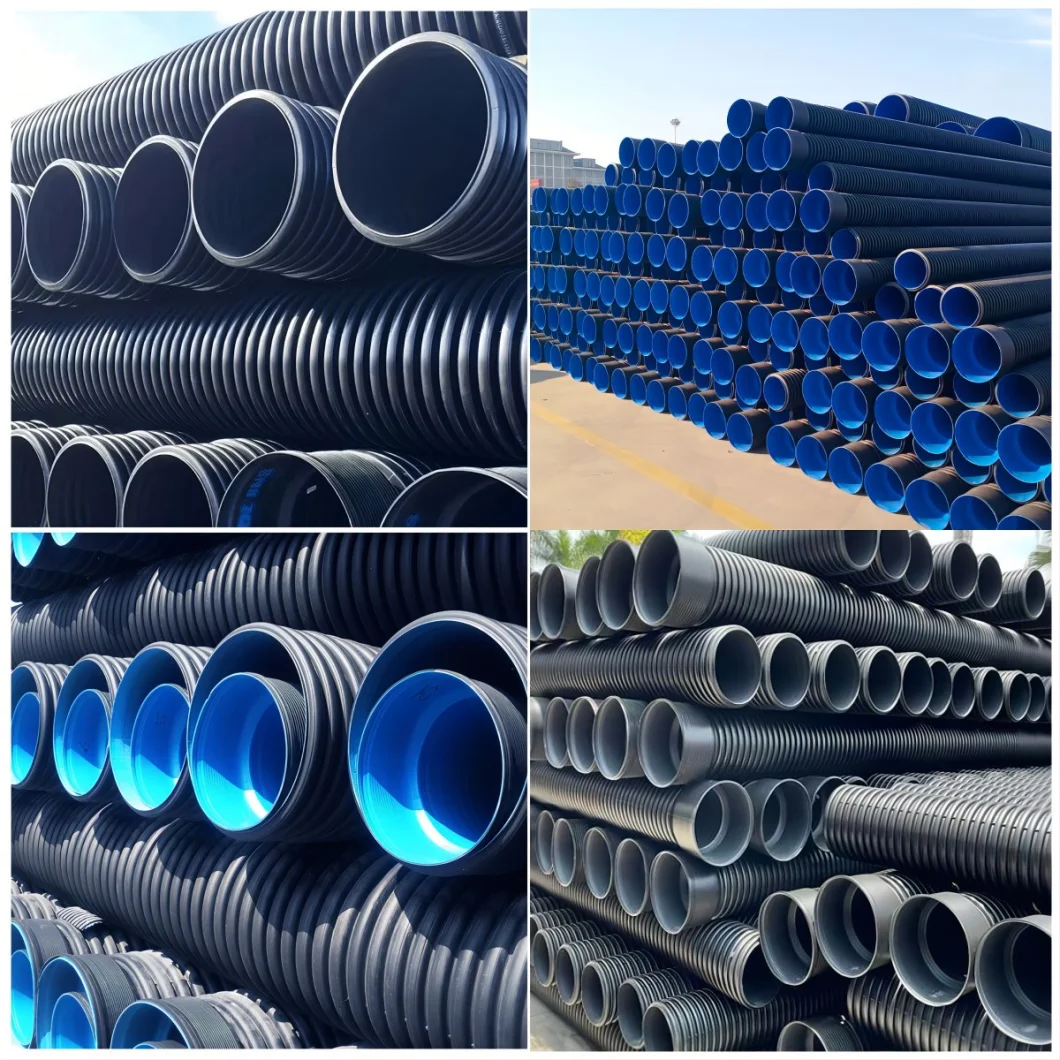

High-Quality and Economical Corrugated PipeIntroduction:HDPE double wall corrugated pipes is a new type of pipe with annular outer wall and smooth inner wall. Its main raw material is high-density polyethylene. This products are suitable for gravity and low pressure drainage system of urban or industrial sewage, sanitary sewage, rainwater drainage, etc. HDPE steel belt reinforced spiral corrugated pipes are the third generation of steel - plastic composite structure pipe prepared by two - step molding process. This product combines the rigidity of steel strips with the corrosion resistance of polyethylene for lighter weight and higher strength. The products can be widely used in urban sewage pipes, bridge and culvert road sewage and drainage pipes, agricultural irrigation pipes, water source water intake pipes and so on.

Product Parameters

HDPE Double Wall Corrugated Pipes:

| DiameterDN/ID(mm) | Minimum Mean Inside Diameter(mm) | Minimum Laminated Wall Thickness(mm) | Minimum Inner Wall Thickness(mm) | Suggestion Connection Length(mm) |

| 200 | 195 | 1.5 | 1.1 | 54 |

| 300 | 294 | 2.0 | 1.7 | 65 |

| 400 | 392 | 2.5 | 2.3 | 74 |

| 500 | 490 | 3.0 | 3.0 | 85 |

| 600 | 588 | 3.5 | 3.5 | 96 |

| 800 | 785 | 4.5 | 4.5 | 118 |

| 1000 | 985 | 5.0 | 5.0 | 140 |

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

| IDX | DiameterDN/ID(mm) | Minimum Mean Inside Diameter(mm) | Minimum Inner Wall Thickness(mm) | Minimum Laminated Wall Thickness(mm) | The Biggest Pitch(mm) | Minimum Strip Thickness(mm) |

| 1 | 300 | 294 | 2.5 | 4.0 | 75 | 0.4 |

| 2 | 400 | 392 | 3.0 | 4.5 | 85 | 0.4 |

| 3 | 500 | 490 | 3.5 | 5.0 | 100 | 0.5 |

| 4 | 600 | 588 | 4.0 | 6.0 | 110 | 0.5 |

| 5 | 700 | 685 | 4.0 | 6.0 | 115 | 0.5 |

| 6 | 800 | 785 | 4.5 | 7.5 | 120 | 0.7 |

| 7 | 1000 | 985 | 5.0 | 8.0 | 150 | 0.7 |

| 8 | 1200 | 1185 | 5.0 | 8.0 | 180 | 0.7 |

| 9 | 2000 | 1985 | 6.0 | 9.0 | 235 | 1.0 |

Physical Properties:

HDPE Double Wall Corrugated Pipes:

| Item | Unit | Index | ||

| TIR | ≤10% | |||

| Flexible Ring | The pattern is smooth and the wall is not broken | |||

| Ring-stiffness | SN2 | KN/m² | ||

| SN4 | KN/m² | |||

| SN8 | KN/m² | |||

| Oven Test | No bubbles, no delamination, no cracking | |||

| Creep Ratio | ≤4 | |||

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

| IDX | Item | Unit | Index | ||

| 1 | Ring-stiffness | SN8 | KN/m² | ≥8 | |

| SN10 | KN/m² | ≥10 | |||

| SN12.5 | KN/m² | ≥12.5 | |||

| 2 | TIR | ≤10% | |||

| 3 | Peel Strength(23ºC±2ºC) | N/cm | ≥100 | ||

| 4 | Flexible Ring | The tube wall is not broken, and the two walls are not detached. | |||

| 5 | Oven Test | No delamination, no cracking. | |||

| 6 | Tensile Strength Of Laminated Wall Of Pipe | 300≤DN/ID≤500 | N | ≥600 | |

| 600≤DN/ID≤800 | N | ≥840 | |||

| 900≤DN/ID≤1200 | N | ≥1020 | |||

| 7 | Creep Ratio | ≤2 | |||

Production Application

1. Public works: buried underground for drainage pipes and sewage pipes. 2. Road engineering: used for railway, highway infiltration ditch or drainage pipe. 3. Industry: widely used in sewage pipelines in industrial areas. 4. Construction engineering: used for building rain pipe, underground drainage pipe, drainage pipe, exhaust pipe, etc. 5. Landfill sewage collection pipe. 6. Large port and wharf engineering: drainage pipe and drainage pipe for large airport, port and wharf engineering. 7. Sports ground: drainage ditch and drainage pipe used for golf course, football field and other sports ground. 8. Water conservancy project: Used as head pipe, irrigation pipe. 9. Mine: used for ventilation, blasting, drainage pipe, pulp pipe, etc. 10. Communication engineering: used for railway, highway communication pipe, communication cable pipe and optical cable protection pipe. 11. Water storage system: Used to intercept slow water flow in the water storage system. 12. Agricultural engineering: farmland, garden, tea garden, forest belt as irrigation pipeline.

1.Are you a factory or a trading company?

We are a professional manufacturer.

2.How is your manufacturing capability?

China's old-fashioned manufacturer, the domestic market has cooperated with the local government and local leading construction companies for decades.

3.What services can you provide?

Problems encountered in the construction can be solved. If there is a problem with the pipeline, we will try our best to solve it or reissue it later.

4.Can you change the size for customers?

Of course, the product will be customized according to your needs, but the payment method requires a larger deposit in advance.

5.What are the advantages of your product?

High quality medium quality according to your needs, but fully up to standard and meet your needs, the price is lower than the market price.

6.Can you provide samples?

Yes, but you need to pay for shipping.

7.What are your payment terms?

We accept TT and L/C, and we will issue an account after multiple cooperations.

8.How is the delivery time?

Depending on the quantity of goods, most requirements are generally met within 20 days.

9.Why choose us?

Decades of production experience and construction experience will help you more than the sales value.