China Manufacture Sn12.5 HDPE Krah Pipe for Sewage and Drainage

Basic Info

| Model NO. | HDPE Structure Wall Pipe |

| Contraction Percentage | <0.4% |

| Tensile Strength | 30~40MPa |

| Production Capaction | 300,000t/Year |

| Certificate | ISO9001, CE, Wras |

| Production Standard | GB/CE/ISO.... |

| Length | 6m |

| Ring Stiffness Kn/M | Sn8,Sn10,Sn12.5,Sn16 |

| Connect Way | Rubber Ring/ Electrofusion Joint |

| Transport Package | Customized |

| Specification | DN200-DN2200 |

| Trademark | LANGBOONE |

| Origin | China |

| HS Code | 3917210000 |

| Production Capacity | 300, 000t/Year |

Packaging & Delivery

Package size per unit product 1000.00cm * 1000.00cm * 1000.00cm Gross weight per unit product 1000.000kgProduct Description

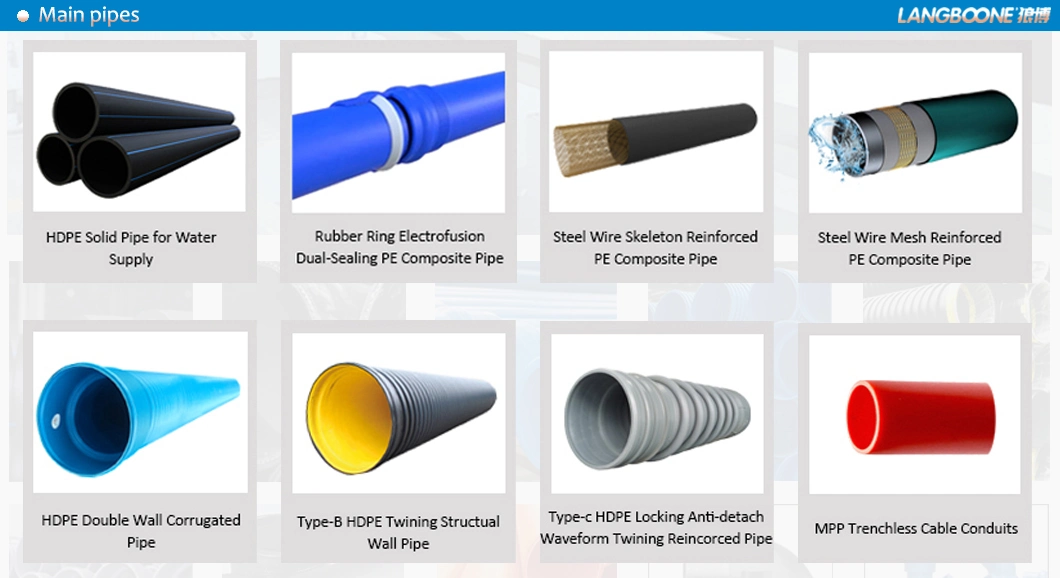

View more products,you can click the product keywords below...

| PIPES | |||

| HDPE pipe | Steel Mesh PE Composite Pipe | Steel Skeleton PE Composite Pipe | Dual-sealing PE Composite Pipe |

| HDPE Double Wall Corrugated Pipe | Type-B HDPE Drainage Pipe | Type-C HDPE Drainage Pipe | MPP Cabel Conduits |

| FITTINGS | |||

| HDPE Electrofusion Fitting | HDPE Butt Welding Fitting | HDPE Fabricated Fitting | PP Compression Fitting |

| Steel Plate Socket ElectrofusionComposite Fitting | Dual-sealing Electrofusion Fitting | HDPE Drainage Fitting | MPP Cable Conduits Fitting |

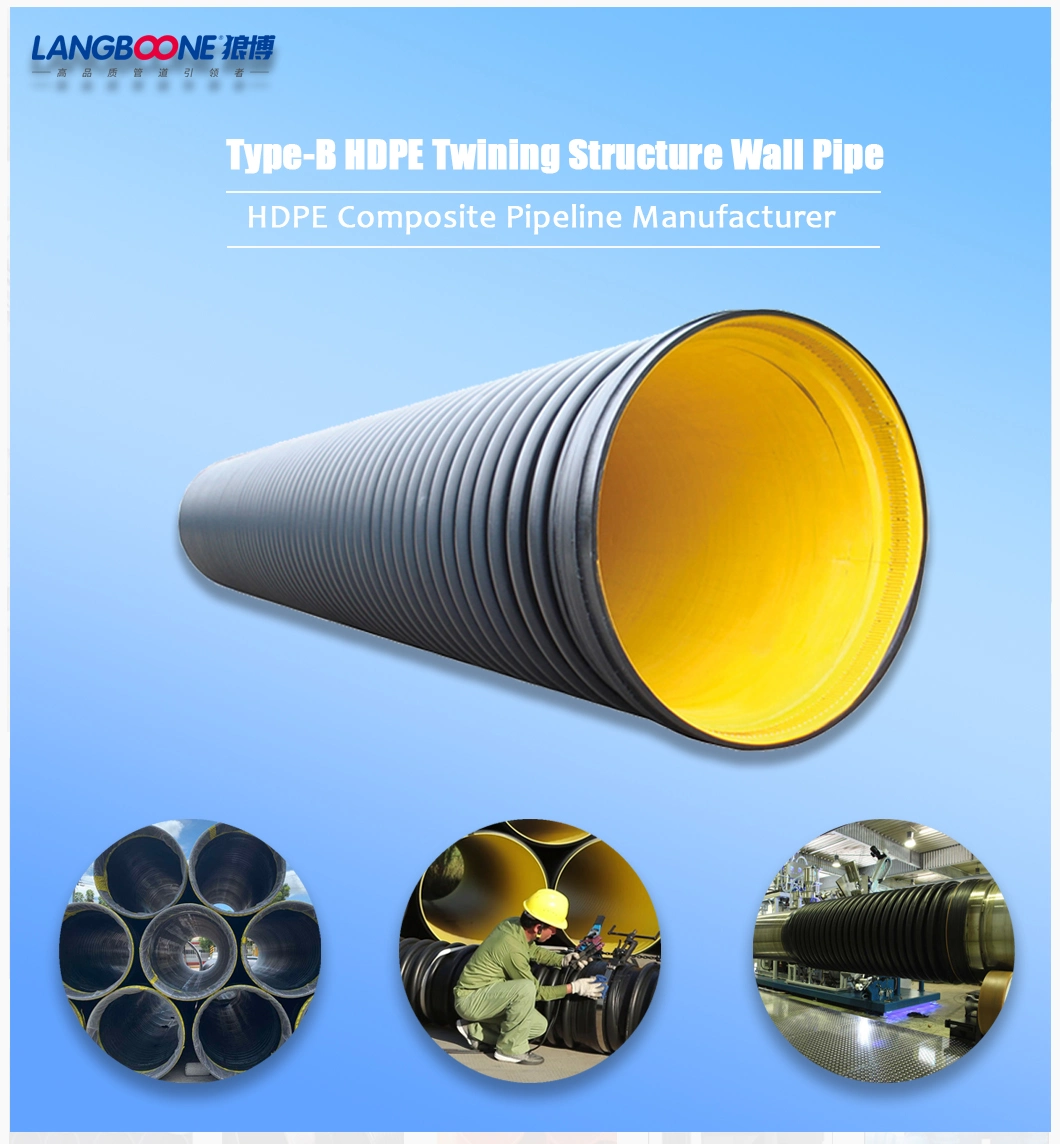

Type-B HDPE Twining Structual Wall Pipe also named Krah pipe is a kind of special-shaped structural wall pipe made by spiral winding process with smooth inner wall and spiral shaped reinforcing rib outer wall, which belongs to flexible pipe. Krah pipes are made of high-density polyethylene by winding forming process in the hot melt state, and are cooled by rolling air cooling before demoulding in the hot state. The pipes gradually dissipate heat and have uniform wall thickness. Krah pipe adopts socket electric fusion connection. Both ends of the pipe are processed into socket and spigot during production, and electric fuse wire is embedded at the socket end. When the pipe is socket connected, only the power supply is connected to complete the welding, which can make the pipeline system achieve zero leakage. This kind of pipe is widely used in urban drainage, municipal drainage, electric power, petrochemical and other fields, and is an ideal replacement for reinforced concrete and cast iron pipes.

Excellent physical properties.High density polyethylene has good rigidity, strength, flexibility and creep resistance. Compared with high density polyethylene, high density polyethylene has better performance of hot melt connection, which is conducive to the installation of plastic pipe.

Corrosion resistance and long service life.PE tube can withstand the erosion of a variety of chemical media, without anticorrosive treatment. It also doesn't promote algae, bacteria or fungi and lasts longer.

Hot wound forming weld is of high qualityThe flat material belt and coating material belt in the molten state extruded from the extrusion machine mouth die are evenly wound on the heated roller mold according to the predetermined position, so that the weld joint quality of the structural wall pipe is more stable. The pipe is cooled by wind and the material is cooled evenly.

High Ring flexibilityPlastic pipe belongs to flexible pipe, in the external pressure load, flexible pipe and rigid pipe to bear the load mechanism is completely different. The flexible pipe can have a large deformation before being destroyed by compression.

Large circulation capacity, economical, excellent installation performance.

Good tightnessThe use of welding connection (hot melting or electric melting), the structure and the tube body itself identity, to achieve the integration of joint and pipe.

Good stress cracking resistance, low temperature impact resistance.

| Type-B HDPE Twining Structure Wall Pipe's Parameter Datas | ||||

| Norminal Inner Diameter (DN/IN) | Average Mean Inner Diameter | Min. Wall Thickness | Minium Melting Lenght for Electic Fusion Connection | Minium Melting Lenght for Rubber Ring Connection |

DN/IN | dim.min | Min.Wall Thickness of inside Layer (B type) e4,Min. | L1.min | LZ.min |

| 150 | 145 | 1.3 | 59 | 43 |

| 200 | 195 | 1.5 | 59 | 54 |

| 250 | 245 | 1.8 | 59 | 59 |

| 300 | 294 | 2.0 | 59 | 64 |

| 400 | 392 | 2.5 | 59 | 74 |

| 450 | 441 | 2.8 | 59 | 80 |

| 500 | 490 | 3.0 | 59 | 85 |

| 600 | 588 | 3.5 | 59 | 96 |

| 700 | 678 | 4.0 | 59 | 108 |

| 800 | 785 | 4.5 | 59 | 118 |

| 900 | 885 | 5.0 | 59 | 125 |

| 1000 | 985 | 5.0 | 59 | 140 |

| 1100 | 1085 | 5.0 | 59 | 152 |

| 1200 | 1185 | 5.0 | 59 | 162 |

| 1300 | 1285 | 5.0 | 59 | |

| 1400 | 1385 | 5.0 | 59 | |

| 1500 | 1485 | 5.0 | 59 | |

| 1600 | 1585 | 5.5 | 59 | |

| 1700 | 1685 | 5.5 | 59 | |

| 1800 | 1785 | 6.0 | 59 | |

| 1900 | 1885 | 6.0 | 59 | |

| 2000 | 1985 | 6.0 | 59 | |

| 2100 | 2085 | 6.0 | 59 | |

| 2200 | 2185 | 7.0 | 59 | |

LANGBOONE HDPE double wall corrugated pipe and type-b,type-c pipes can be joined by a variesty of methods includng mechanical joints and a range of thermal fusion procedures,the main methods are Butt Fusion,Electrofuion joint,socket fusion joint,flange adaptor joint and compression joint.