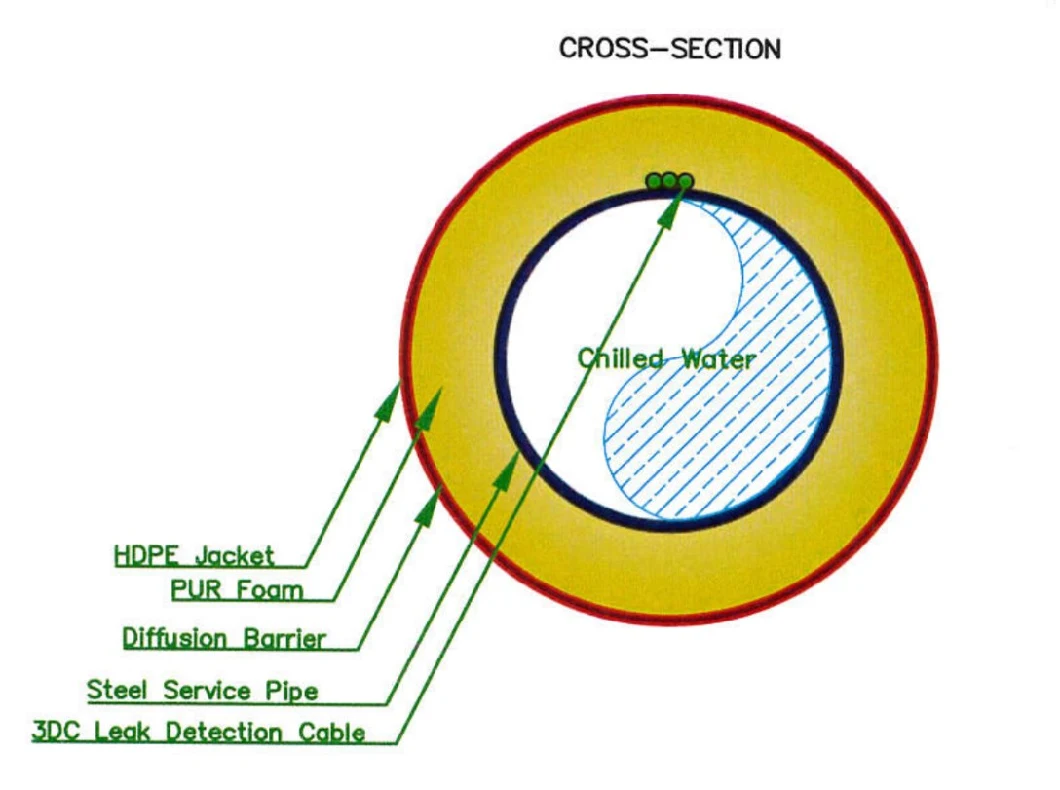

Underground Thermal Insulation Steel Pipe Withpolyurethane Foam and HDPE Jacket for Chilled Water Gas Oil Project

Product Description steal pipe with Polyurethane foam insulation and HDPE jacket sleeve Main Indexes of Polyurethane ins

Basic Info

| Temperature Classification | High Temperature Piping |

| MPa Classfication | High Pressure Piping |

| Material | Carbon Steel |

| Standard | ASTM, GB, API, DIN, JIS |

| Diameter | 200-2000mm |

| Medium | Liquid, Fluids with Solid Particle, Gas |

| Cross-Section Shape | Round |

| Connection Type | Welding |

| Color | Black |

| Usage | Asphalt, Lubricants, Solvent, Fuel, Petroleum Coke |

| Type | Heavy Crude Oil |

| Application | Base Oil, Derivatives, Industrial Lubricant, Oil |

| Transport Package | Standard Package |

| Specification | DN25-DN1400 |

| Trademark | OEM |

| Origin | China |

| HS Code | 7304192000 |

| Production Capacity | 50000ton/Year |

Product Description

Product Descriptionsteal pipe with Polyurethane foam insulation and HDPE jacket sleeve

| Name | Pre-insulated Pipe |

| structure | work steel pipe/polyurethane insuation layer /HDPE outer protection pipe |

| the material of insuation layer | polyurethane foam |

| Installation Method | 1.cold installation 2.Prestress Installation 3.Preheat Installation Method 4.One-Time Compensator Installation Method |

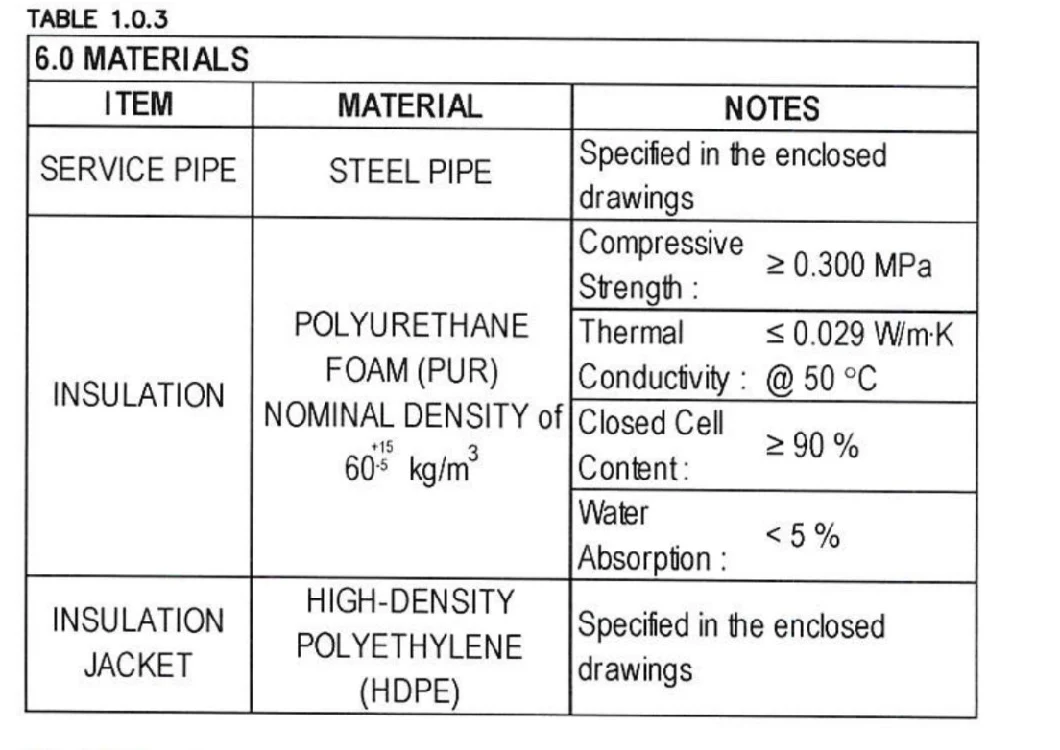

Main Indexes of Polyurethane insulation layer

| indexes | preference Standard | unit | standard requirement |

| Density | CJ/T114-4.3.2 | kg/m3 | ≥60 |

| Average | CJ/T114-4.3.1 | mm | ≤0.5 |

| Percentage of close area | CJ/T114-4.3.1 | % | ≥ 88 |

| Compressive strength | CJ/T114-4.3.3 | MPa | ≥ 0.3 |

| Water Absorption | CJ/T114-4.3.5 | % | Immersion in boiling water 90 minute,bubble water absorption should be not more than 10% |

| Cavity | CJ/T114-4.3.1 | ≤ 0.033 |

Specification of pre-insulated Pipe

| Specifications (mm) | steel pipe OD×Thickness (mm) | Outer protection tube diameter ×Wall thickness (mm) | Insulation thickness (mm) | Unit weight Kg/m |

| 32/90 | 32×2.8 | 90×2.5 | 26.5 | 3 |

| 45/110 | 45×2.8 | 110×2.5 | 30.0 | 4 |

| 57/120 | 57×3.0 | 120×2.5 | 29.0 | 6 |

| 60/125 | 60×3.5 | 125×3.0 | 29.5 | 7 |

| 76/140 | 76×4.0 | 140×3.0 | 29.0 | 9 |

| 89/160 | 89×4.0 | 160×3.0 | 32.5 | 11 |

| 108/180 | 108×4.0 | 180×3.0 | 33.0 | 13 |

| 133/200 | 133×4.5 | 200×3.2 | 30.3 | 17 |

| 159/250 | 159×4.5 | 250×3.9 | 41.6 | 22 |

| 219/315 | 219×6.0 | 315×4.9 | 43.1 | 39 |

| 273/365 | 273×6.0 | 365×5.6 | 40.4 | 49 |

| 325/420 | 325×7.0 | 420×7.0 | 40.5 | 67 |

| 377/500 | 377×7.0 | 500×7.8 | 53.7 | 81 |

| 426/560 | 426×7.0 | 560×8.8 | 58.2 | 94 |

| 478/600 | 478×7.0 | 600×8.8 | 52.2 | 104 |

| 529/630 | 529×7.0 | 630×9.8 | 40.7 | 114 |

| 529/655 | 529×7.0 | 655×9.8 | 53.2 | 117 |

| 630/760 | 630×8.0 | 760×11.5 | 53.5 | 158 |

| 720/850 | 720×8.0 | 850×12.0 | 53.0 | 181 |

| 820/960 | 820×10.0 | 960×14.0 | 56.0 | 252 |

| 920/1055 | 920×10.0 | 1055×14.0 | 53.5 | 281 |

| 1020/1155 | 1020×10.0 | 1155×14.0 | 53.5 | 312 |

| 1220/1380 | 1220×12.0 | 1380×16.0 | 64.0 | 444 |

| 1420/1602 | 1420×14.0 | 1602×16.0 | 75.0 | 590 |

| 1. | good insulation properties |

| 2. | low heat loss |

| 3. | heat loss is 25% of the traditional pipe. |

| 4. | energy saving |

| 5. | about 30 yeas move the service life, low cost |

| 6. | has a strong waterproof and corrosive resistance and high mechanical strength |

| 7. | no attached trench ,can be directly buried in the ground or water. |

| Standard | API 5L | ||

| Grade | PSL-1 | API 5L - Gr.B/X42/X46/X52/X60/X70 etc. | |

| ( Material) | PSL-2 | ISO3183 - L245/L290/L320/L360/L415/L485 etc. | |

| Minimum Order Quantity | 1 Ton | ||

| Outside Diameter Ranges | PSL-1 | 0.405-80(in) or 10.3mm-2032mm | |

| PSL-2 | 4 1/2 -80(in) or 114.3mm-2032mm | ||

| Wall Thickness Ranges | SCH10~SCH160 Or STD,XS,XXS Or 1.73mm~59.54mm | ||

| Length | For 20Ft Container | 4.8m-5.8m | |

| (negotiable) | For 40Ft Container | 4.8m-12m | |

| Most common choice | 6m, 12m | ||

| Type | Welded | ERW,LSAW/SSAW | |

| Seamless | Cold Drawn,Hot Finished,Hot Expanded | ||

| Cap (negotiable) | Pipe size should under DN600 | ||

| Pipe End | Plain end | All sizes | |

| Bevel end | Pipe size above DN50, and the thickness should greater than 3.2mm | ||

| Our advantages | ·Diverse products(Steel pipes, pipe fittings, other fittings) | ||

| ·Any third party inspection is accepted by we company. | |||

| ·Quick response in quotation,delivery,after-service. | |||

| ·Focus on pipe & tube solution for project application. | |||

| Nominal size of Pipe | Minimum thickness of normal coating in mm |

| Up to DN100 | 1.8 |

| Over DN100 up to DN250 | 2.0 |

| Over DN250 to below DN500 | 2.2 |

The products can also be customized according to the customer's special design and requirements.

previous:

PE HDPE Plastic Gas Supply PE Pipes

Send to us