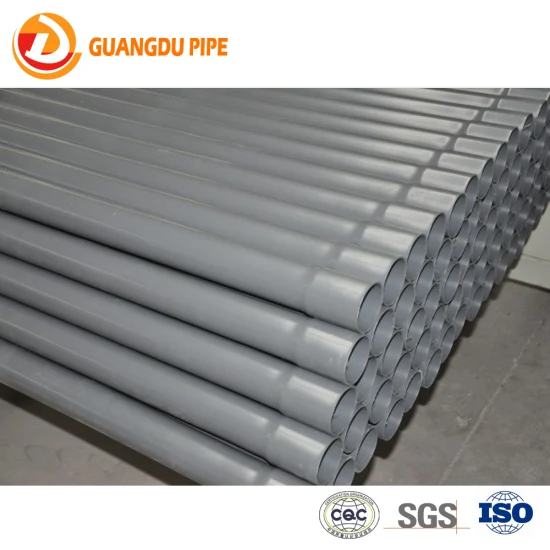

Large Diameter PVC-U Double Wall Corrugated Pipe for Drainage

Product Introduction HDPE (High Density Polyethylene) Double Wall Corrugated Pipes are for gravity and low pressure sewe

Basic Info

| Model NO. | Double Wall Corrugated Pipe |

| Tensile Strength | 81~130MPa |

| Hardness | Hard Tube |

| Color | Gray, White, Customized |

| Shape | Round |

| Pressure | Pn6~Pn25 |

| Use | Drainpipe, Water Supply Pipe, Threading Pipe |

| Length | 6m |

| Transport Package | Container |

| Specification | DN200~DN800 |

| Trademark | Lu′ao |

| Origin | China |

| HS Code | 39172100 |

| Production Capacity | 100000 Tons Per Year |

Product Description

Product IntroductionHDPE (High Density Polyethylene) Double Wall Corrugated Pipes are for gravity and low pressure sewerage and drainage, such as waste water, sanitary sewer and storm sewerage for municipal or industrial use. The pipes provide important benefits and distinct advantages for sewer and drainage applications.

Double Wall Corrugated Pipe Features:1.Intensity and Stiffness (ability of enduring geographical conditions load);

2.Hydraulic features (ability of transporting liquid);

3.Sealability (no giveaway, prevent polluting environment);

4.Long Lifespan (corrosion resistant, resistance to abrasion);

5.Easily to install;

6.Comprehensive economical features

First: Intensity and stiffness. Because plastics embedded pipe is flexible pipe and it endures the press with the soil around in correct design and construct that plastics embedded pipe doesn 't need the same intensity and stiffness as rigid concrete drain pipe.

Next: In hydraulic features, plastics pipe's resistance of fluid is less than concrete pipe because of it's slippy inner surface. It's proved by practice that smaller diameter plastics pipe can attain required the same flow rate than concrete pipe at the same slope. Plastics pipe can decrease the slope rate at the same diameter (decrease construction workload ).

Third: In sealability, Plastics pipes' connection is credible. (flexible sealing ring bell and socket link).

Four: Plastics pipe has many advantages in useful lifespan and corrosion resistant. Sewage and rainwater transported by embedded pipe is always aggressive, acidity or causticity. Sewage has powerful corrosiveness for example industrial water. Plastics embedded pipe has better inoxidizability than metallic conduit and concrete pipe. Plastics pipe's abrasion resistance is better.

Five: Prominent advantage in installation: light weight, longer length (less connect), low require for pipe ditch and foundation, easy connecting and quickly constructing. Plastics pipe's virtue is prominent in city's crowded area and bad geological area (for example high ground water level and flaccid foundation).

Last: plastic embedded pipe's virtue is being discovered in comprehensive economic level. The price of plastic embedded pipe is higher than concrete pipe. But it is approved by installation practices in domestic and international market; in all projects?cost of plastics embedded pipe was lower than concrete pipe if the design and construction is correct. The cost of double wall-corrugated pipe is as similar as concrete gripping pipe. Its price decreases 30%-40% than faucet concrete pipe. Double wall-corrugated pipe can reduce the construction period. Its economic feature is apparent.

Major technical indicators of HDPE Double Wall Corrugated pipe

Density: 941kg/m2 ~965 kg/m2 ;

Refracton coefficient: 1.54nd;

Water absorption<0.01%;

Tensile strength:20-35Mpa;

Elastic modulus:800MPa; Stretch yield strength: 20MPa;

The ring strength of pipe should equal or over 4KN/ m2;

HDPE Double Wall Corrugated Pipe Application:1.Rainfall and sewage drainage in municipal engineering

2.Industrial waste water and plot sewage drainage

3.Brine well transporting bittern, fishery transporting water

4.Mine ventilation and drainage project

5.Farming irrigation and drainage

6.Wall pipe of excavate project (double wall corrugated pipe with holes

7.Water conservancy project

8.Safeguard pipe of low voltage cable and communication cable

9.Expressway embedded pipe

Specification

| Nominal Inside Dia.(mm) | Average Inside Dia.min(mm) | Outside Thicknessmin(mm) | Inside Thickness min(mm) | Connection Lenght(mm) |

| 200 | 195 | 1.1 | 1.5 | 54 |

| 300 | 294 | 1.7 | 2 | 64 |

| 400 | 392 | 2.3 | 2.5 | 74 |

| 500 | 490 | 3 | 3 | 85 |

| 600 | 588 | 3.5 | 3.5 | 96 |

| 800 | 785 | 4.5 | 4.5 | 118 |

Company Profile

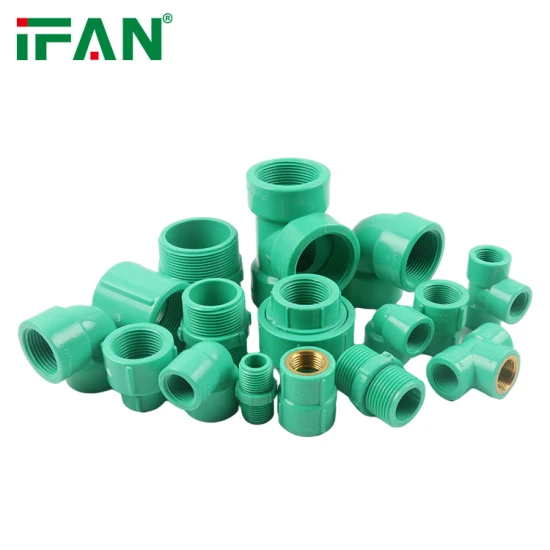

Shandong Luao New Material Technology Development Co. Ltd Was established in 2003, which is an enterprise concentrating manufacturing PLASITC pipes and fittings. The leading products are Fosite Brand PP-R PIPE AND FITTING, HDPE PIPE AND FITING, UPVC pipe and fittings, PE-RT, PEX pipes & fittings and plastic tubing welding equipment. It has advanced automatic machines.

We pursuit the quality is the first and the service is also important. Shentong has passed ISO9001, ISO4001. We have our own test lab for quality control. Our brand Forsite is famous in home and overseas market. SHENTONG promises: Reasonable price, fast delivery and satisfactory service. Hope to cooperate with more customers for mutual development and benefits, warmly welcome potential buyers to contact us.

FAQ

1

Q: What is the Raw material ?

A: 100% virgin raw material.

2

Q: What is your MOQ?

A: As customers' requests.

3

Q: why choose us?

A: We are a professional manufacturer with competitive price, good quality and fast delivery time.

4

Q: How to buy the product?

A: Send email to me, we will reply to you within one day.

5

Q: Can you make special Design and logo on product?

A: Yes, very easy.

6.

Q: What is the shipping port?

A: Shanghai or Qingdao port.

Send to us